Winter Fuel Prep: What’s the best option?

Winter is approaching, and fleet owners and operators should gear up for the cold season and start their winter fuel prep. One significant concern during winter is ensuring that your diesel fuel doesn’t gel. Gelling can occur around 5-10º F, while ice formation and filter plugging can occur at temperatures as high as 32º F.

Traditionally, people use kerosene blends such as an 80/20 (80% diesel, 20% kerosene) throughout the winter to prevent diesel from solidifying. However, proper winter diesel additives are more effective and cost-efficient in preparing fuel for frigid weather. The decision to use kerosene should depend on the severity of the cold conditions.

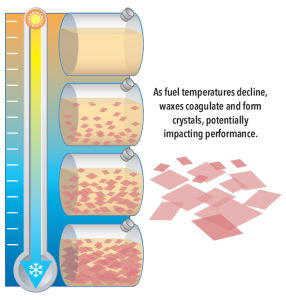

Why does diesel fuel solidify?

As temperatures decrease, the paraffin (wax) present in ULSD fuel can solidify, causing a blockage in the engine’s fuel flow. Additionally, any water in the fuel may freeze on the surfaces of fuel filters, leading to a restriction in the fuel flow, which can also damage the engine.

Why not blend kerosene?

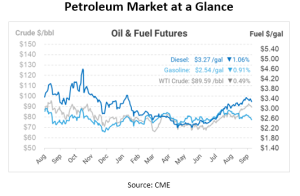

Since kerosene costs $.50-$1.00 more than diesel, every additional 10% blended makes your fuel about 5-10 cents more expensive per gallon. Plus, it’s not great for fuel efficiency, as kerosene has less energy than diesel, so you’ll need more fuel to do the same amount of work. You can learn more about kerosene and its applications here.

When to use kerosene?

The kerosene blend becomes crucial in regions where temperatures plummet to -20°F or lower, such as in Minnesota and other northern states. In these extremely cold conditions, kerosene should be the additive choice to prevent diesel from gelling. In Canada, diesel fuel is treated at the refinery to meet the country’s harsh winter conditions, so additional treatment typically is not needed.

Winter Fuel Prep: Diesel Additives

Winter diesel additives, called cold-flow improvers, are put into diesel fuel to prevent gelling. A winter diesel additive, such as Arsenal ColdPRO, can significantly improve fuel performance during winter.

When properly blended, additives modify the structure of the waxy molecules in the fuel, preventing them from glomming together and creating filter-plugging sheets.

Contact Mansfield today to learn more about winter additives and how to start you winter fuel prep and keep your fleet running smoothly in the cold weather.

This article is part of Daily Market News & Insights

Tagged: additives, Fuel Quality, Winter Fuel Prep, winter season

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.