3 Risks of Missing Underground Fuel Tank Inspections

Underground storage tanks (USTs) are essential for industries that depend on storing petroleum and hazardous materials. From gas stations to manufacturing facilities to transport companies, these tanks quietly do their job beneath the surface. But ignoring their maintenance can lead to significant problems—leaks that contaminate soil and groundwater, and costly cleanups that could cripple a business.

This is where proper maintenance and the right technology come into play. If you’re responsible for USTs, today’s article will help you understand why these practices matter and how to stay ahead of compliance requirements while protecting your investment and the environment.

Official Inspections

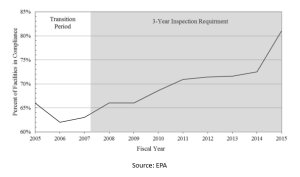

For years, many states conducted UST inspections irregularly—sometimes every four years or longer. This led to serious issues, including frequent leaks and low compliance rates. Recognizing the problem, Congress passed the Energy Policy Act of 2005, mandating that USTs be inspected at least once every three years.

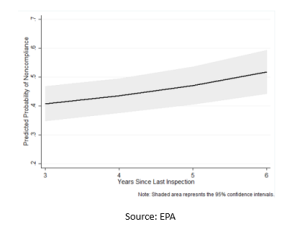

Why does inspection frequency matter? A study released by the United States Environmental Protection Agency (EPA) showed that more inspections lead to better compliance. Facilities that were already compliant during prior inspections improved even further with consistent oversight, while those struggling to meet standards showed gradual progress.

Nationally, compliance rates increased from 66% in 2005 to 81% in 2015, thanks in large part to the new inspection schedule. These inspections catch problems before they become disasters, encouraging facility owners to adopt proactive habits.

The Cost of Neglecting USTs

Failing to maintain USTs doesn’t just risk noncompliance—it puts your business, community, and environment in harm’s way. When a tank leaks, the consequences can be staggering:

- Groundwater Contamination: Nearly half of all Americans rely on groundwater for drinking water. A single leak can seep harmful substances into this vital resource.

- Cleanup Costs: According to the EPA, cleanup costs vary depending on the extent of contamination and state cleanup standards. Removing a small amount of contaminated soil may cost around $10,000, while the average cost of cleaning up a UST with more extensive contamination is approximately $154,000. If groundwater is affected, cleanup expenses can range from $100,000 to over $1 million.

- Long-Term Environmental Damage: A leak today can cause damage that lasts for decades, affecting property values, ecosystems, and public health.

Proper maintenance and regular inspections are your first line of defense against these risks. Are your

USTs ready for inspections?

Technology Role

Here’s where things get interesting. Automatic Tank Gauges (ATGs) have revolutionized UST management. Common ATGs on the market include Veeder-Root, Pneumercator, ProGauge, Evo, and more.

An ATG will monitor:

- Fuel Levels: Ensure accurate inventory management.

- Leak Detection: Monitor interstitial spaces to identify leaks.

- Temperature and Volume Adjustments: Track fuel expansion and contraction due to temperature changes.

Why does this matter? For underground tanks, you can’t rely on visual checks. Therefore, ATGs are more than optional upgrades—they are a regulatory necessity. The EPA requires leak detection systems for all USTs to ensure that even small leaks don’t go unnoticed. With features like automated alerts and remote monitoring, ATGs help businesses stay compliant while simplifying day-to-day operations.

They also streamline inventory management, reducing losses from theft, evaporation, or temperature-related fuel expansion. By investing in these systems, UST owners not only meet EPA standards but also gain valuable insights into their operations.

Mansfield Energy: Your Partner in Compliance

Are your tanks up to date? When was your last inspection? Addressing these questions today can save headaches—and costs—tomorrow.

Navigating UST regulations can be overwhelming, but Mansfield Energy offers comprehensive support to keep businesses compliant and efficient. With services ranging from Tank installation to ATGs to maintenance programs, Mansfield ensures UST systems meet the highest standards.

Mansfield also provides training and consultation, helping companies understand regulatory requirements and adopt best practices. By partnering with experts, businesses can avoid guesswork and focus on running their operations smoothly. Ready to learn more? Call us today!

This article is part of Daily Market News & Insights

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.