10 Ways to Optimize Your Fuel Program: Part 2

In this second part of the “10 Ways to Optimize Your Fuel Program” article, we pick up where we left off after exploring the initial five strategies in Part 1. Just to recap briefly, in the first part, we covered essential topics like fuel centralization, back office automation, fuel tank optimization, inventory management, and fleet card optimization.

Today, we’ll dive into the remaining five strategies that round out the comprehensive toolkit we created to help you achieve excellence in your fuel program management.

- Fuel Quality

Fuel quality is often overlooked aspects of fuel management but can have a significant impact on a business’s bottom line. Neglecting fuel quality can lead to corrosion in storage tanks, resulting in costly repairs and decreased fuel efficiency. Moreover, microbial growth and water contamination can disrupt operations and lead to unexpected vehicle downtime. By investing in fuel quality management, organizations can avoid unexpected expenses, enhance fuel efficiency, and maintain the integrity of their fuel systems, ultimately contributing to long-term cost savings and operational stability.

- Winter Treatment Optimization

Winter treatments are a crucial strategy for businesses operating in regions with cold weather conditions. Often, organizations default to using higher blends of kerosene all winter long, which can significantly increase fuel costs. However, by carefully assessing winter fuel requirements and utilizing cold-weather additives when lower blends are sufficient, companies can achieve substantial savings.

- Repair and Maintenance Program

A well-structured repair and maintenance program is another important component of an effective fuel management program. Beyond simply maintaining your fuel tanks themselves, this program empowers businesses to manage their expenses, set quality standards for equipment and repairs, and gain insights into their fleet’s specific needs. By collecting and analyzing data on repair and maintenance, companies can take a proactive approach to their operations, preventing costly breakdowns and downtime. This approach allows organizations to leverage their resources effectively, facilitating timely parts orders and service calls. Instead of reacting to issues as they arise, a centralized program enables negotiations with suppliers, resulting in cost savings and smoother overall operations.

- Fuel Dispensing Control and Tracking

Implementing fuel controllers and advanced dispensers not only enhances security but also ensures that fuel is dispensed accurately and securely. This technology eliminates fuel shrinkage due to theft and fraud, which can be a significant source of financial loss, sometimes reaching up to 5% of expenses. Moreover, precise data collection and tracking capabilities aid in the reconciliation process, providing transparency and accountability. By maintaining control over fuel dispensing, organizations gain valuable insights into consumption patterns and can help companies optimize fuel usage and reduce costs.

- Price Risk Management

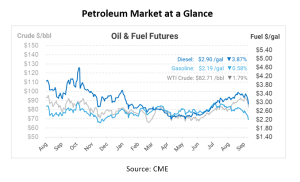

The unpredictability of fuel prices can significantly impact budgets and profitability. Therefore, having mechanisms in place to secure price stability is crucial. This approach enables businesses to meet their budgetary goals, safeguard profitability, and avoid the negative impacts of seasonal price fluctuations. Predictable accounting and invoicing reconciliation become more manageable with price risk management, allowing for greater financial transparency and control. When companies effectively manage price risks, they can gain a competitive edge, ensuring stability and predictability in their fuel procurement processes.

As you can see, optimizing your fuel program requires a comprehensive strategy that encompasses different components of procurement and management. These ten strategies we shared with you this week provide a roadmap to cost savings, efficiency improvements, and risk management, ensuring your fuel program operates at its best. Whether you focus on one or adopt all, these tools can significantly enhance your organization’s fuel management practices.

Looking for professional guidance?

Mansfield Energy is here to help you make the most out of your fuel program. Beyond the 10 best practices shared this week, there are dozens of ways to make sure your fuel program is future-proof and running smoothly. You have other priorities shifting your attention elsewhere – let Mansfield empower you to achieve your goals without excessive oversight.

Mansfield Energy serves as a reliable partner and fuel supplier, equipping companies with the necessary resources for optimizing their fuel programs. Our objective is to simplify energy management for your organization, providing you with the right products, tools, and expertise to turn your fuel problems into solutions.

Reach out to Mansfield to see how we empower customers to get the products, logistics, and services they need to be competitive. Contact us today!

This article is part of Daily Market News & Insights

Tagged:

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.