Set It and Forget It: How Automated Inventory Management Keeps Your Fleet Rolling

Are you still manually checking your tank readings and calling in an order of fuel? If so, you’re missing an opportunity to automate and remove hassle from your day.

Automated Inventory Management – Tank inventory monitors – whether robust ATGs that measure environmental compliance each day or simple probes tracking your inventory only – are not new technology. Most businesses with bulk fuel storage have implemented cloud-connected devices to keep track of what’s in their tanks. A few old souls still manually stick a tank to confirm levels, but this is a rarity. Despite the proliferation of connected tanks, though, many companies still expect a local site manager or corporate fuel buyer to inspect online inventory readings and order fuel when tanks get low.

If you’re still manually ordering fuel, you could save time, cost, and energy by switching to automated inventory management.

What Tank Monitors Can Do

Tank monitoring systems are usually equipped with analytic dashboards that provide instant insights into key performance indicators such as tank levels, temperature, fuel consumption, and leak detection. The reports and dynamic market analytics enable the management team to make informed, strategic decisions.

From GPS mapping and tank tracking to detailed usage history, most systems offer a plethora of data points. Fuel managers can monitor everything from current gallons and available capacity to temperatures and battery levels. This comprehensive data access enables effective planning and forecasting, significantly reducing the likelihood of inventory shortages or excesses.

Benefits of Inventory Management

By outsourcing the fuel ordering process to your fuel supplier, you’ll benefit in a number of ways:

- Save Time – Every time your site manager or central fuel buyer checks on tank levels, they’re distracted from their main job of keeping the business moving forward. That daily time and attention adds up over the course of a year – just a 5-minute daily effort, over the course of the year, is over 20 hours of wasted time. At $30/hr – that’s more than $600 in wasted productivity! Why spend that at every site when outsourcing is much faster and cheaper?

- Operational Improvement – when the former person in charge of fuel leaves the business, gets promoted, or retires, who takes over? Are they ready on day 1, or do you have process risk? An empty fuel tank can shut down your operation, costing you revenue and wasted labor expenses. Outsourcing to automated, intelligent systems designed to always keep your tank full ensures a more reliable supply setup, avoiding runout risks.

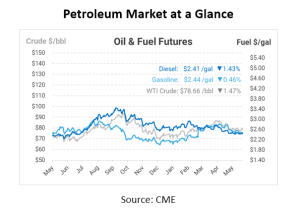

- Market Intel – Your employees have a business to run; they don’t have time to stay well-informed on local fuel market trends as well. Is there a hurricane five days out and heading towards the site? The local personnel may or may not know yet… but your fuel supplier is well aware and already acting to top of inventory managed sites to get ahead of any disruption. Local refinery shutdown delaying deliveries? A site may wait until the last minute to order, but a fuel supplier knows the situation and initiates orders early to keep their customers full.

Ready to get started?

Mansfield offers a variety of services to help maintain your company’s operational well-being. Mansfield integrates with many of the most popular tank probes and ATGs, so we can often take over your inventory management very quickly. Some sites may need to install tank monitors, and Mansfield can provide a turnkey rollout plan to ensure every site is connected with reliable and affordable equipment tailored to your needs.

Stop letting turnover, last-minute ordering, and market disruptions dictate your ability to keep your fuel tanks full. Switch to automatic inventory management today.

This article is part of Daily Market News & Insights

Tagged:

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.