What Is It – Winter Diesel Additives

With cold weather starting to set in, diesel truckers begin prepping in ways that others may not realize. That’s because diesel fuel has a chilling secret – at very low temperatures, the fuel can thicken into a waxy gel that plugs filters and clogs engines. To stay in action, fleets must prepare their diesel tanks with additives to prevent gelling before it starts. In any market where temperatures might drop below 10° F, knowing about winter diesel additives is a must. So let’s dive into this important seasonal topic in today’s What Is It article.

What Are Winter Diesel Additives

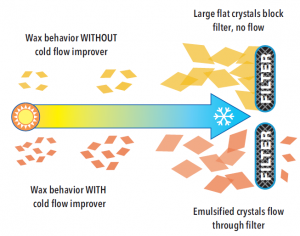

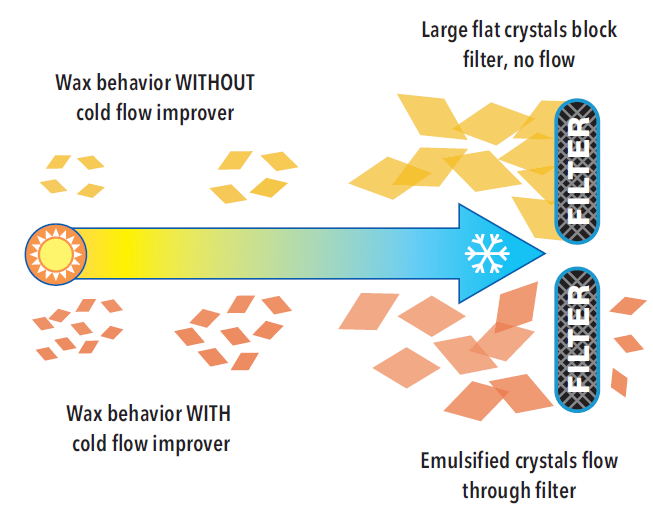

Winter diesel additives, also called cold-flow improvers, are put into diesel fuel to prevent gelling. Using a winter diesel additive, such as Arsenal ColdPRO, can greatly improve fuel performance during an extreme winter event. Ideally administered at the time of fuel delivery, cold-flow additives must be properly mixed into the fuel. When properly blended, additives modify the structure of the waxy molecules in fuel, preventing them from glomming together and creating filter-plugging sheets.

Without additives, these wax sheets then get drawn into the fuel filter, either at the fuel dispenser or in the fuel system of the engine. This wax buildup continues to compound until the filter is clogged and soluble fuel is unable to penetrate the filter. When this happens, it starves the nozzle or engine of fuel and shuts down operations.

Why Does Diesel Fuel Gel?

Ultra-low sulfur diesel #2 (normal diesel fuel) contains natural waxes called paraffin wax. Tiny wax molecules float in the fuel along with carbon molecules and other substances. Wax is not always a bad thing – when the waxy molecules remain small, they can easily pass through a fuel filter.

Paraffin waxes have their perks. Paraffin waxes are combustible, meaning they add power when burned in the engine. Paraffin waxes make up a portion of the energy content in fuel – that’s why candles are made from paraffin wax. On the flip side, kerosene (also known as diesel #1) has far less paraffin wax, and as a result, it has a lower energy content. You may notice lower fuel efficiency and power when burning kerosene blends.

Waxy paraffins cause problems when they glom together and plug filters. The Cloud Point is the point at which diesel fuel becomes cloudy from waxes lumping together. The colder the weather, the more paraffins drop out of the fuel and gel together. Larger paraffin chunks clog filters, preventing fuel from flowing through. The point at which your filter plugs and operations cease is called the CFPP – Cold Filter Plug Point. The CFPP is the most important metric for fleet operators since that’s the point at which operations are disrupted.

Cloud Point vs. CFPP

The Cloud Point and the CFPP both vary depending on geography and fuel quality. In general, when properly treated with winter cold flow additives, the CFPP will be 18° below the Cloud Point – called the 18° Rule. If your fuel is treated with additive and gets cloudy at 10° F, filters will be plugged at -8° F. Without additive, the CFPP could be anywhere from -8° F to +9° F; cold flow additives protect you up to 18° below whatever your fuel’s cloud point is. Kerosene, on the other hand, lowers the Cloud Point, typically buying you 3° lower Cloud Point for each 10% kerosene blended in.

What Other Factors Affect Gelling?

Local fuel quality can be a big factor. During Winter 2017-18, Midwest markets saw increased gelling events due to fuel quality concerns at refineries. Diesel fuel specifications in the US do not specifically address fuel gelling concerns, so refined fuels can meet all specs 100% and still gel (on the flip side, Canadian refiners are required to blend winter-operable fuels). Since all fuel suppliers get their diesel fuel from the same terminals and pipelines, no one supplier will have an advantage during these events – the key is proper testing and treatment.

Tank conditions also matter. Significant quantities of biofuel can have higher cloud points, though this isn’t true in all areas. Another challenge is water. Water freezes at 32° F – which can also clog your filters and pumps. Keeping your tank clean can prevent freezing and gelling issues.

What Are the Alternatives to Winter Additives?

Some fleet managers swear by kerosene as the solution to winter fueling. Indeed, kerosene is an effective – and at times critical – component to maintaining winter operability. But kerosene can be much more expensive than ULSD #2, and during the winter markets may struggle with supply availability. So while kerosene is a great option, it shouldn’t be the only approach to winter fueling.

Other winter products can help fleets maintain operability. Using a water dispersant prevents water from staying in your fuel, so you won’t get frozen sludge flowing into your equipment. Emergency deliquefiers, such as Mansfield’s FIRST+AID, are a remedy used when fuel has already gelled.

This article is part of Additives

Tagged: coldpro, diesel, gelling, kerosene, Winter Diesel Additive

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.