What’s That: Vapor Recovery Units

Vapor Recovery Units (VRUs) are designed to capture methane emissions from storage tanks and other low-pressure vented gas sources in oil and gas operations, including pipeline pigging activities, compressors, and dehydrators. VRUs can be installed on individual storage tanks or across multiple tanks. In today’s “What’s That Wednesday,” we’ll dive into how VRUs work, their role in reducing carbon footprints, and the economic benefits they provide.

Have you ever wondered what happens to the lingering vapors that escape from oil and gas tanks? If left uncontrolled, these vapors can cause environmental and health risks.

What are Vapor Recovery Units?

Vapor recovery units are straightforward devices designed to capture vapors from low-pressure tanks with an efficiency of around 95%—they require about 5% of the time for annual maintenance. When installed on storage tanks, these units prevent the release of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) into the atmosphere by collecting and compressing the vapors for reuse or sale. Because VRU technology is relatively inexpensive, it offers great financial benefits in markets that can utilize the recovered, energy-dense vapors.

VRUs are primarily utilized to minimize emissions from crude oil and condensate storage tanks. However, when a VRU is already installed, the vapor collection system can be adapted to capture emissions from additional low-pressure vent sources on-site, including pipeline pigging operations, compressor seal vents, blowdown vents, and dehydrator vents.

How Vapor Recovery Units Work

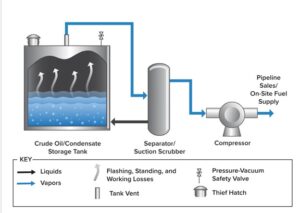

Not only do VRUs mitigate environmental pollution, but they also allow operators to utilize the captured gases as valuable resources. They can be installed on a single storage tank or multiple tanks, like a gathering/boosting station tank battery. When VRUs operate, they extract hydrocarbon vapors from the storage tank at low pressure (0.25–2 psig) and route them to a suction scrubber, which separates and returns condensed liquids to the tank. The remaining vapors pass through a wet gas compressor designed for low suction pressure. A control pilot regulates the system, shutting down the compressor and allowing vapor backflow when liquid levels drop, preventing tank vacuum formation.

VRUs typically work like this:

- Vapor Collection – Hydrocarbon vapors from storage tanks are drawn into the VRU.

- Liquid Separation – A suction scrubber removes condensed liquids, returning them to the tank.

- Compression – The VRU compresses the remaining vapors to increase pressure.

- Utilization – The recovered gas is sent to sales pipelines, used as fuel, or processed for valuable components.

- Emission Prevention – Any excess vapors are controlled or recycled to minimize environmental impact.

How are Emissions Reductions Captured?

The EPA’s STAR Program promotes the development and adoption of technologies and standards to minimize methane emissions in the oil and gas industry. Cutting methane emissions not only mitigates environmental impact but also enhances operational efficiency, reduces risk, and reinforces a company’s commitment to sustainability. There are multiple methods for estimating emissions, including the use of emission factors, direct measurement, and simulation software. The specific approach depends on the emission source controlled by the VRU, but in general, post-VRU emissions are estimated by applying a 95% reduction to pre-VRU emission levels.

The Inventory of U.S. Greenhouse Gas Emissions and Sinks (GHGI), specifically, the Natural Gas and Petroleum Systems section, provides emission factors for storage tanks, reciprocating compressors, and centrifugal compressors, offering a standardized reference for industry calculations.

Additional Benefits of Vapor Recovery Units

Vapor Recovery Units (VRUs) offer additional benefits beyond methane emissions reduction. They help companies comply with EPA methane regulations and state-level emission reduction targets, ensuring regulatory compliance. Additionally, captured gas can be sold or used as fuel, turning what would otherwise be wasted emissions into a source of revenue. VRUs also enhance operational efficiency by reducing tank pressure fluctuations, which minimizes maintenance costs and prevents equipment damage.

From a safety perspective, they lower the risk of explosions and fires by controlling volatile emissions. Furthermore, integrating VRUs supports corporate sustainability goals by reducing carbon footprints and demonstrating a commitment to environmental responsibility. By adopting VRUs, companies can improve compliance, profitability, safety, and efficiency, making them a great investment for both economic and environmental reasons.

This article is part of Daily Market News & Insights

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.