Winterizing Your Fuel: Why Your Region Matters

Winter is a challenging season for fleet owners and operators. The colder the weather, the greater the risk of fuel gelling or clogging, which can derail operations. The key? Treating your fuel with the appropriate additive blend strategy that considers the region where your fleet operates. Don’t know how? Then, this article is for you!

Winter additives, or cold-flow improvers, are crucial to prevent fuel from gelling or clogging in cold conditions. They lower the Cold Filter Plugging Point (CFPP) and pour point of diesel, ensuring that fuel flows through engines and filters without interruption. However, blindly applying the additive won’t be enough—each region has its own temperature patterns, and proper blending must account for those variations. You can learn here why diesel tends to gel at low temperatures.

Blending for your Region

Mansfield’s winter season spans from October 15th to March 31st, but these dates can vary based on location and weather conditions. It is during this period that winter additives are most commonly used. These additives are designed to depress the CFPP, and they are often paired with kerosene (ULSD #1), which further lowers the cloud point and CFPP. In areas with extreme cold, the combination of kerosene and other additives is necessary for optimal performance.

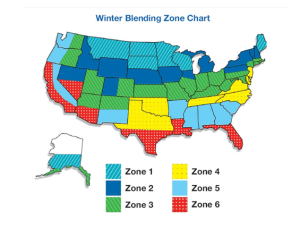

To make things easier, the industry has established a reliable system for blending winter additives. Mansfield Energy, for instance, uses the Tenth Percentile Minimum Ambient Air Temperatures, as defined in the ASTM D975-10c for Diesel Fuel Winter Blending Strategies, to assign proper treatment protocols. These guidelines, based on October-to-March temperatures, break the country into six cold-weather zones, ensuring that each location gets the fuel treatment it needs to withstand local weather conditions.

There are certain regions where the standard blending protocol may not be enough. For instance, Northern Plains Markets and biodiesel-blended states often face more extreme conditions, requiring extra attention. These regions should consider increased additization beyond normal guidelines to ensure continued operability during the harshest parts of winter. In this case, speak to your fuel or additives supplier to learn more about their protocols or programs.

Additives for Cold Weather

When preparing your fuel for winter, using the right additives is key to maintaining performance. Here are some of the most effective winter additives you should consider:

- Cold Flow Improver: This additive is designed to prevent gelling by lowering the CFPP of diesel fuel. It is a staple in winter blending strategies, helping maintain fuel flow in freezing conditions. Fleet operators use cold flow improvers to protect engines from the harmful effects of extreme cold by ensuring smooth combustion.

- Re-Liquefier: Sometimes, despite preventive measures, fuel can gel in extremely cold weather. Re-liquefiers help restore fuel flow in gelled systems, acting as a quick solution to get vehicles running again.

- Water Dispersant: Water in fuel tanks can freeze and cause severe engine issues in winter. Water dispersants are designed to remove moisture from fuel tanks, preventing ice formation and ensuring smooth engine operation.

- Biocide: Cold weather can exacerbate the growth of bacteria and fungi in fuel tanks, which can clog filters and reduce performance. Biocide Additive is an antibacterial and antifungal agent that keeps your fuel free of microbial contamination, protecting engines from unexpected breakdowns.

Plan Ahead to Prevent Downtime

Just as planning your fleet’s routes is crucial for efficiency, properly preparing your fuel for winter is essential for avoiding costly breakdowns. Mansfield’s Arsenal ColdPRO is a program to improve your fuel’s cold-weather performance, offering consistent and accurate treatments, minimizing kerosene cost, and performing nationwide fuel testing.

Blending winter additives according to your region not only helps ensure that your fleet runs smoothly, but it also reduces unnecessary costs and downtime. Don’t wait for winter to hit—take the time now to evaluate your regional needs and adjust your blending practices accordingly.

With the right strategy in place, you can keep your fleet running smoothly throughout the winter season, regardless of where you operate. If you haven’t already, reach out to Mansfield to learn more about Arsenal ColdPro. Don’t wait; contact us today to secure a worry-free winter for your fuel needs.

This article is part of Daily Market News & Insights

Tagged:

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.