What’s That: Enhanced Oil Recovery (EOR)

During the production and development of U.S. crude oil, reservoirs can contain up to three distinct phases, and there are three techniques used to achieve enhanced oil recovery (EOR). In today’s What’s That Wednesday article, we will unpack what enhanced oil recovery (EOR) is and how it functions in the energy sector. Although enhanced oil recovery can be complex, the use of EOR techniques leads to an increased amount of recoverable oil. Let’s explore how EOR techniques have been successful in preserving oil!

What is EOR?

To understand the enhanced oil recovery (EOR) process, it’s necessary to first grasp what enhanced oil recovery entails. Enhanced oil recovery refers to the techniques used to extract oil that has not been recovered through the initial two oil recovery methods employed during crude oil production. It comes into play following the development and production phases of crude oil, which consist of three stages: primary, secondary, and tertiary recovery.

In primary recovery, oil is extracted using the reservoir’s natural pressure or gravity to push the oil into the wellbore, often with the aid of mechanical pumps that bring it to the surface. This method typically recovers only about 10% of the oil originally present in the reservoir. To extend the productive life of the field, secondary recovery methods are used, which usually involve injecting water or gas to push the oil toward the wellbore. This can increase the total oil recovered to between 20 and 40% of the original amount. As much of the easily accessible oil has already been extracted from U.S. oil fields, producers are now exploring various tertiary or enhanced oil recovery methods. These advanced techniques have the potential to recover 30 to 60%, or even more, of the original oil initially present in the reservoir. There are three major categories of EOR that have proven successful in this endeavor.

Three Major Categories of Enhanced Oil Recovery

EOR techniques are categorized into three major methods. These methods have proven successful and offer a range of benefits for enhanced oil recovery. One of these methods is thermal recovery, which involves injecting heat into the reservoir to lower the oil’s viscosity, making it easier to extract. Steam injection is a common approach within this category. According to the Office of Fossil Energy and Carbon Management, thermal methods constitute more than 40% of enhanced oil recovery production in the U.S., with the majority of this activity concentrated in California. Chemical recovery utilizes various chemicals, such as surfactants and polymers, to modify the properties of the oil or the surrounding fluids, thereby enhancing oil mobilization and displacement. This method represents only 1% of enhanced oil recovery (EOR) activities in the United States.

The third method is gas injection, which involves introducing gases like carbon dioxide, nitrogen, or natural gas into the reservoir. This process helps maintain pressure, reduce oil viscosity, or mix with the oil to improve its flow. Gas injection accounts for approximately 60% of EOR production in the United States. Each of these techniques increases the amount of oil that can be recovered from a reservoir beyond what conventional methods achieve, but they are often challenged by high costs and, at times, unpredictable results and varying effectiveness.

How EOR Affect the Energy Economy?

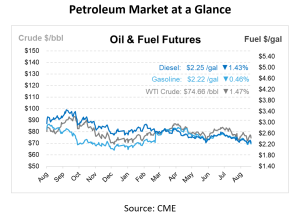

Enhanced oil recovery (EOR) methods are complex and expensive, typically employed only after primary and secondary recovery techniques have been exhausted. The economic viability of EOR depends on various factors, including oil prices; if these factors do not justify the expense, EOR may not be pursued by producers. As a result, some oil and gas may remain in the reservoir if their extraction is not financially viable. Development costs are a critical factor in the financial feasibility of carbon dioxide EOR projects. These costs are difficult to generalize because they vary significantly based on the project’s type, scale, location, and reservoir depth. Additionally, costs can vary greatly depending on well configurations and whether existing wells and equipment can be repurposed for carbon dioxide EOR. On the other hand, increased oil recovery offers an economic advantage, with the resulting revenue influenced by current oil prices. The economic viability of any procedure is influenced by prevailing prices, which are affected by various factors. Generally, more procedures and those with higher costs become economically feasible only when prices are higher.

This article is part of Daily Market News & Insights

Tagged: Enhanced Oil Recovery (EOR)

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.