Sludge in Your Tank? Learn What to Do!

Having on-site storage can present a variety of benefits, such as supply security, lower procurement costs, and operational control. However, it’s essential to recognize the importance of proper maintenance to preserve fuel quality and equipment functionality. Without the correct maintenance program, above and below-ground tanks can accumulate sediment, water, and eventually harmful microorganisms. Microbial growth and corrosion can lead to more frequent filter replacements, slow fueling, and equipment damage. Detecting and addressing sludge accumulation is crucial to preventing contamination, maintaining operational efficiency, and ensuring the longevity of your equipment.

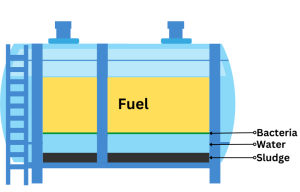

Sludge is a dark, viscous substance that can accumulate over time and can typically be found at the bottom of fuel storage tanks. Comprised of dirt, debris, excess moisture, rust flakes, and microorganisms, it threatens the integrity of stored liquids and the tank itself.

Detecting the presence of sludge isn’t always easy – especially if you don’t have a maintenance program in place. Signs of accumulation might include hindered liquid flow through dispensers, pipes, and valves, excessive buildup of foreign matter in filters, or cloudy or opaque fuel. Sludge buildup can catalyze corrosion and rust formation, further jeopardizing the tank’s structural integrity.

Neglecting tank maintenance often allows sludge to accumulate unchecked. A study by the Environmental Protection Agency (EPA) revealed that 83% of the underground tanks (USTs) analyzed exhibited moderate to severe levels of corrosion. Even more concerning was the revelation that only 25% of tank owners were aware of this corrosion before the study.

Addressing Sludge

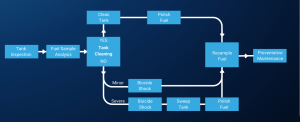

To start, fuel samples – taken from both the middle and the bottom of the tank – should be tested by a laboratory to determine the extent of the tank contamination. The fuel’s quality shows the level of sludge accumulation and dictates the needed next steps – a tank-bottom sweep and fuel polishing might suffice in some circumstances, while a full cleaning of the tank interior may be required for more severe cases. In the case of a tank cleaning, all the fuel should be removed and filtered, while the inside of the tank would be scrubbed and cleaned. It is important to note that a tank cleaning expert should help you analyze and determine what would work best for removing the sludge and other contaminants from your tank. Don’t hesitate to contact your fuel provider.

Once your tank is clean and contaminant-free, preventing or mitigating new sludge formation becomes paramount. Keep in mind that scheduled maintenance inspections are essential. Inspect the tank, pumps, and containment area for any signs of damage or leaks. Additionally, fuel samples should be taken to check for impurities like sediment or organic growth, which can indicate the need for treatment by an additive expert.

Regular testing in a lab every six months helps verify fuel quality and cleanliness. Also, routine use of biocides and additives can prevent water accumulation, microbial growth, and other contaminants. Click here to learn How to Save Money and Avoid Common Fuel Tank Repairs.

Your Trusted Partner

Mansfield Energy services thousands of commercial, industrial, and government tanks across the US, with the experience and expertise to ensure your tanks are treated right every time. Through its nationwide network of qualified technicians, Mansfield can help you get the help your operation needs quickly, reliably, and at a fair price.

If your business operates bulk fuel tanks across the US, it’s time to get serious about equipment maintenance and upkeep. Get bigger reach, broader solutions, and better advice by choosing Mansfield as your fuel tank repair & maintenance partner. Contact us today!

This article is part of Daily Market News & Insights

Tagged:

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.