What’s That: Bulk Fuel Tanks

Are you considering installing a bulk tank but find yourself unsure if it’s the most practical choice for your business? Understanding the specific needs of your company and the logistics of implementing a bulk fuel system is essential in making an informed decision.

Bulk fuel tanks are large containers that store and dispense fuel for various purposes, such as farms, fleets, industrial sites, etc. Bulk fuel tanks can range in size from a few hundred gallons to tens of thousands of gallons, depending on the fuel demand and storage space. (Note: this article uses “bulk fuel tank” to refer to the entire fuel system, not only the storage tank.)

Bulk fuel tanks offer many benefits, such as convenience, cost-effectiveness, and security, but they also pose some challenges, such as environmental risks, regulatory compliance, and maintenance requirements. So let’s dive into the world of bulk fuel tanks to learn about the different styles and applications.

Different types of Bulk Fuel Tanks

Single-Wall vs Double-Wall:

Fuel tanks can have one or two walls keeping the fuel contained. Single-wall bulk fuel tanks require less building materials,, but they require a secondary means of containment, such as a dike, a curb, or a pit, to prevent spills and leaks. If you see an old fuel tank surrounded by a short retainer wall, t’s possible it could be a single-wall tank.

For environmental and safety reasons, most modern fuel tanks in the US and Canada are double-wall tanks. Double-wall bulk fuel tanks have an inner and an outer wall, with a space between them (called the interstitial space) that can be monitored for leaks. Some of these tanks also have materials in the interstitial space, such as concrete, to provide more ballistics protection.

Vertical vs. Horizontal:

Vertical bulk fuel tanks are cylindrical and stand upright on the ground. They are suitable for storing large volumes of fuel (20K gallons and above), but they may require more space and height clearance than horizontal tanks. Vertical fuel tanks are common for very large storage purposes, such as at a refinery or a fuel terminal. Some heavy industrial users may also have vertical fuel tanks to support heavy demand.

Horizontal bulk fuel tanks are cylindrical and lie horizontally on the ground. They are suitable for storing smaller volumes of fuel (20K gallons and below), with a lower center of gravity that provides stability against weather, wind, and earth shifting. Horizontal tanks are more common to see in end-use applications.

Aboveground vs Underground:

Aboveground storage tanks (ASTs) are situated above the ground surface, offering versatility in material storage. Because the tanks are above ground, they are easier to install and maintain, and also easier to monitor for potential leaks and required inspections. These tanks are readily reachable, facilitating routine checks and repairs. However, ASTs are more exposed to the elements, which can lead to aethetics degredation. ASTs receiving full truckload deliveries require trucks to have a pump to push product into the tank.

In contrast, underground storage tanks (USTs) are buried beneath the ground surface. Made of steel, fiberglass, or concrete, USTs mitigate fire and explosion risks by their subterranean placement. USTs offer benefits such as reduced space requirements and longevity. Moreover, their subterranean placement shields them from environmental elements, ensuring a longer lifespan and more stable temperatures for fuel. USTs can be gravity fed by a fuel truck, reducing excess fees on deliveries. On the other hand, USTs are harder to access for repairs, and a leak cannot be visibly seen for prevention.

Parts of a Bulk Fuel Tank

While technically the “tank” is a specific part of the entire fuel system, in this case we’re using it to refer to the entire fuel system, from storage to monitoring to dispensing. Although different systems could have more components (including spill buckets, additional piping, gauges, etc), these are the most important major components of a bulk fuel storage system:

Fuel Tank: The tank is the portion that actually stores the fuel. Your fuel demand will determine whether the tank you need is 250 gallons or 25,000 gallons, or somewhere in between. Because this part of the tank holds the fuel for the longest period of time, this is also where fuel quality concerns come into play.

Pump: The fuel pump pulls product from near the bottom of the tank into the other parts of the fuel system. The pump is an essential component of the fueling process; picking the right duty cycle and durability is essential to ensure it lasts.

Dispenser: Fuel in the tank is no good without a way to get it out! Whether you have a full retail dispensing setup or a simple hose and nozzle, the dispenser controls the flow of fuel into your equipment.

Tank Gauge: The tank gauge tracks what’s in your tank, monitoring levels to ensure there are no leaks or other environmental hazards. Many gauges also connect to the cloud, allowing for inventory management and reporting.

Fuel Management System: The final component is optional but provides significant insights. The fuel management system sits between the pump and the dispenser, only allowing users to fuel if they have the right access (such as a credit card, a fleet card, or a PIN, among other options). The FMS authenticates the user and tracks who dispensed fuel and when.

Regulations Impacting Fuel Tanks

Bulk fuel tanks are subject to various federal, state, and local regulations that safeguard human health and the environment from potential threats posed by bulk fuel tanks. Some of the major regulations affecting bulk fuel tanks are:

- The Spill Prevention, Control, and Countermeasure (SPCC) regulation (40 CFR Part 112) requires facilities with bulk fuel tanks to prepare and implement a plan to prevent and respond to oil spills.

- The Underground Storage Tank (UST) regulation (40 CFR Part 280) sets the technical standards and requirements for the design, installation, operation, and closure of USTs.

- The National Fire Protection Association (NFPA) standards, such as NFPA 30, NFPA 30A, NFPA 31, NFPA 37, NFPA 110, etc., provide fire safety codes and practices for the storage and handling of flammable and combustible liquids.

Benefits of a Bulk Fuel Tank

Buying fuel in bulk can often result in lower per-unit costs compared to purchasing smaller quantities more frequently. Additionally, having a bulk tank ensures a steady supply of fuel, reducing the risk of running out of fuel during critical operations. This is particularly advantageous during emergencies when retail stations may be closed. Moreover, having a bulk tank on-site can help protect your fleet from fraud and theft associated with fuel purchased at retail stations, offering greater visibility and accountability.

Furthermore, having a bulk fuel tank eliminates the need for frequent trips to refuel, which can save time and increase productivity for your drivers. This strategic approach to fuel management aligns with successful businesses’ priorities, directing efforts toward more productive and profitable endeavors. By bringing refueling to your home base, you can spare the time and hassle of traveling elsewhere for fuel.

Bulk tanks also allow you to have a clear understanding of your fleet’s fuel situation and quality. Many bulk tanks come equipped with monitoring systems that provide real-time data on fuel levels and can alert you when fuel is running low. This enables more efficient management of fuel usage. For fleets invested in sustainability, having a bulk tank allows you to control the type of biodiesel blends you receive, such as B5, B10, or B20. This level of control over fuel quality and type can further support your business’s environmental initiatives. You can learn more about the benefits of a bulk fuel tank here.

In summary, bulk fuel tanks provide convenience, savings, and safety for diverse needs. Available in various types and materials, each with its own advantages and disadvantages, they are customized to meet specific requirements. Despite challenges such as environmental concerns and regulatory compliance, diligent planning and maintenance can ensure their sustained efficiency and reliability, ensuring uninterrupted access to fuel for your business.

Count on Mansfield’s Expertise

When deciding to install a fuel tank, partner with a reliable supplier that can fulfill your unique needs. Mansfield’s team of fuel experts is ready to help you say goodbye to unnecessary freight costs, high retail premiums, limited delivery timeframes, and compromised supply security.

Mansfield offers a complete lineup of fueling system design, installation, and maintenance services. If you have been contemplating fuel tank installation, give our experts a call and let them help you find a solution right for you and your business. Mansfield would be happy to assist you in evaluating the best tank alternatives if you are interested in accelerating your company to the next level. Contact us today to get started.

This article is part of What Is It Wednesday

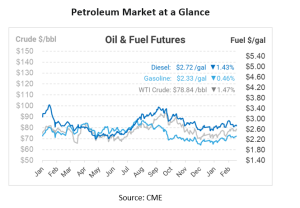

Tagged: crude, Daily Market News & Insights, diesel, gasoline, oil prices

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.