Why More Diesel Tanks are Gelling This Winter

(With contributions from Alan Apthorp)

During the winter, most fleet operators understand the need to keep their diesel fuel protected. Cold temperatures cause wax to drop out of diesel fuel, coagulating together to clog diesel tank and engine filters and shut down operations.

This year, diesel users in some areas have noticed that fuel is gelling at higher temperatures than normal. Even fuel treated with additive and kerosene is not as protected as usual. Extremely cold weather experienced throughout the country has exacerbated these challenges over the past week. The recent cold snap had a higher-than-average impact on fuel operations, and the culprit may not be what you expect.

Prepare your fleet for the next cold snap.

Why Does Gelling Occur?

Before I explain what’s happening to diesel fuel this year, it’s helpful to understand why gelling occurs and how kerosene and additive affect the process.

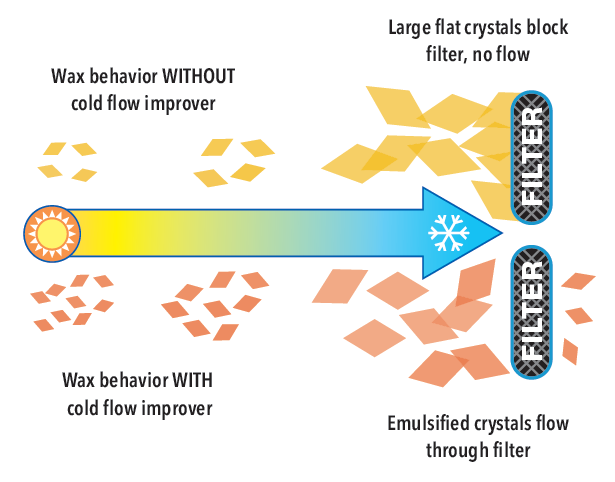

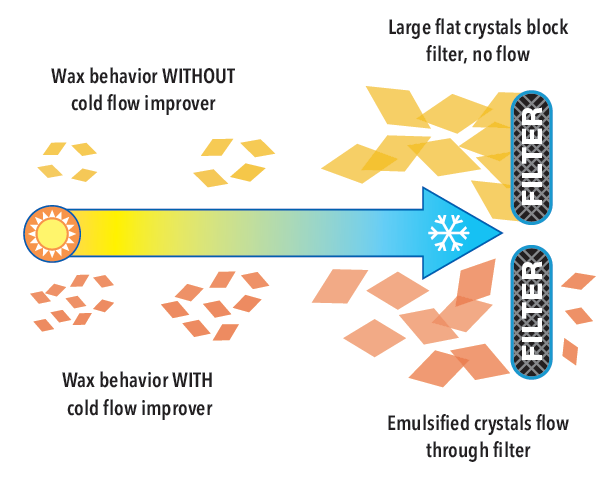

Ultra-low sulfur diesel #2 (normal diesel fuel) contains natural waxes called paraffin wax. Tiny wax molecules float in the fuel along with carbon molecules and other substances. Wax is not always a bad thing – when the waxy molecules remains small, they can easily pass through a fuel filter.

Paraffin waxes have their perks. Paraffin waxes are combustible, meaning they add power when burned in the engine. Paraffin waxes make up a portion of the energy content in fuel – that’s why most candles are made from paraffin wax. On the flip side, kerosene (also known as diesel #1) has far less paraffin wax, and as a result it has a lower energy content. That’s why you may notice lower fuel efficiency and power when burning kerosene blends.

Those waxy paraffins cause problems when they glom together and plug filters. The Cloud Point is the point at which diesel fuel becomes cloudy from waxes lumping together. The colder the weather, the more paraffins drop out of the fuel and gel together. Larger paraffin chunks clog filters, preventing fuel from flowing through. The point at which your filter plugs and operations cease is called the CFPP – Cold Filter Plug Point. The CFPP is the most important metric for fleet operators, since that’s the point at which operations are disrupted.

The Cloud Point and the CFPP both vary depending on geography and fuel quality. In general, when properly treated with winter cold flow additives, the CFPP will be 18° below the Cloud Point – called the 18° Rule. If your fuel is treated with additive and gets cloudy at 10° F, filters will be plugged at -8° F. Without additive, the CFPP could be anywhere from -8° F to +9° F; cold flow additives protect you up to 18° below whatever your fuel’s cloud point is. Kerosene, on the other hand, lowers the Cloud Point, typically buying you 3° lower Cloud Point for each 10% kerosene blended in.

To summarize:

- Waxes in fuel bind together when temperatures fall, and get stuck on fuel filters.

- With additives, filters will clog when temperatures are 18° below the Cloud Point.

- Kerosene can lower the Cloud Point, giving you additional protection at a rate of 3° per 10% blend.

- The Cloud Point varies based on refinery production and geography.

Poor Winter Fuel Quality This Winter

As I mentioned above, Cloud Points are usually less than 10° F for diesel fuel. That means cold flow additives should protect fuel down to -8° F, and kerosene could provide some additional protection. However, new factors this year have fundamentally changed conventional diesel fuel winter performance.

Low crude prices have altered refinery supply chains. With prices so low, refineries are buying from a variety of crude sources, leading to highly variable feed stocks. Diverse feed stocks have made fuel quality less predictable. Diesel fuel specifications have no useful performance standards related to winter operability, so there’s no way to avoid poor quality fuel when it occurs.

Poor fuel quality this year has created two issues for winter operability:

- Cloud Points have been higher in some states, particularly Missouri, Kansas, and Pennsylvania. Cloud Points have been 5°-10° higher than ideal levels. That small difference is important, especially when temperatures are dipping below zero.

- Extremely waxy fuel is causing fuel to gel even when Cloud Point is at ideal levels. This is a major factor behind the increase of gelling incidents last week. Chemical lab tests show high wax contents in fuel in some areas this year, requiring much higher kerosene and additive treatment rates than normal.

These concerns are amplified by biofuel content, which can contribute to higher gelling temperatures. Biofuels are produced using a variety of different oils, ranging from soybeans and corn to animal fat. These can contribute to further filter clogging at cold temperatures. Every gallon of diesel fuel in the U.S. contains up to 5% biofuel, and some states use higher bio blends.

One other contributor, unrelated to fuel quality, is extremely fine fuel filters. During the winter, Mansfield suggests using a 10 micron fuel filter rather than a 4 micron filter. Gelled wax molecules will melt long before they reach engine injectors, so they won’t adversely affect engine performance. Excessively tight fuel filters have been the root cause behind several gelling incidents this year, and needlessly put operations at risk. It’s a small detail, but it can make a significant impact on fuel flow.

Is It Really Gelling?

As a side note, some gelling incidents are caused by water in the fuel, rather than paraffin wax. Like wax, frozen water can clog a fuel filter and cause engines to shut down. Water freezes at much higher temperatures than fuel, so if your filters are causing troubles at 20°-30° F, you may have an ice issue.

Checking whether you have ice in your filter is a fairly simple task. Just remove your fuel filter and if you see a thick waxy substance, you have fuel gelling. To fix it, you will need an emergency reliquefier or kerosene and winter additives to clear your tank. If you see an icy buildup, simply warm the filter to get fuel moving through it once again.

How to Prepare Your Fleet

This winter has already proven to be colder-than-average, so fleet managers should prepare for more cold weather in the coming weeks and months. Despite the challenges, there are steps fleet managers can take to minimize the risk of fuel gelling.

- Test fuel tanks for Cloud Point and CFPP. Fuel testing is even more important this year than in past years. Mansfield recommends pre-season and post-season fuel tests, as well as monthly tests during the winter for Cloud Point and CFPP levels. With proper fuel testing and analysis, fleet managers can address poor quality fuel before it occurs.

- Increase winter fuel treatment rates. Using more winter additive and higher kerosene has been effective in preventing and remediating gelling incidents. Mansfield has begun treating states as far south as Missouri and Kansas with the same treatments we normally use in Minnesota.

- Keep emergency reliquefiers and cold flow additive available on-site. While higher winter treatment rates should prevent gelling, sometimes fuel sits for prolonged periods, or your vehicles may fuel up off-site. With unpredictable temperatures this year, having extra winter additive and emergency reliquefiers such as Arsenal FIRST+AID can keep your fleet running through the extreme winter cold.

While fuel quality challenges this year present unique obstacles for fleet managers, proper winter fuel procedures can help avoid gelling incidents. Using these tools, fleets can successfully maintain operational performance throughout the winter.

This article is part of Alerts

Tagged:

MARKET CONDITION REPORT - DISCLAIMER

The information contained herein is derived from sources believed to be reliable; however, this information is not guaranteed as to its accuracy or completeness. Furthermore, no responsibility is assumed for use of this material and no express or implied warranties or guarantees are made. This material and any view or comment expressed herein are provided for informational purposes only and should not be construed in any way as an inducement or recommendation to buy or sell products, commodity futures or options contracts.